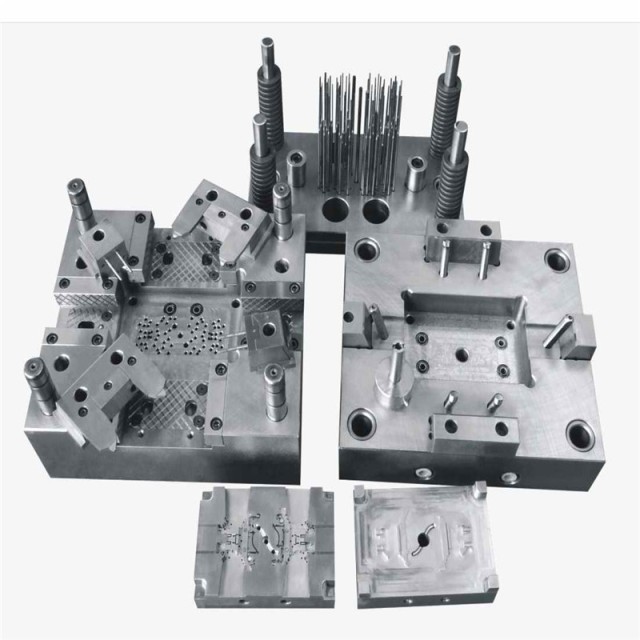

Plastic injection is an industrial process of fabricating products with customized designs. Since the manufacturing process uses high-quality equipment and updated technology features, the products are durable and crack resistant. So, these can be supplied without any transportation losses on the way. The list of products includes a pipe fitting mould, chair Mould, crate Mould, automotive moulds etc. The products fabricated by plastic injection moulding find uses in the home appliance, automobile accessories, piping installations, fittings, etc.

HQMould is based in Taizhou, Huangyan in China. With technological inputs and qualified human resources, the Chinese firm is aiming to become one of the leading plastic injection mould suppliers China.

Types of Mould

- A crate Mould is cast out of pre-hardened steel and a high-speed injection moulding machine.

- Automotive moulds include control panels, shock absorbers in cars. The fabrication technology uses Unigraphics, Solid E, Mold flow, and Solid works.

- A pipe fitting mould is a robust piece of lightweight accessory, made with injection moulding. It finds application in domestic systems like sanitary fittings and heavy duty industrial units like pipelines.

- A chair Mould is an intricate Mould, fabricated with injection moulding. The chair is designed in the initial step when the molten metal is made to flow and assumes a specific shape.

Before selecting a service provider or manufacturer of plastic injection moulded products, clients must ensure that it has proper storage and delivery facilities. Clients must check if the firm complies with quality standards in manufacturing as well as logistics. There are many firms where plastic injection moulded products are formed.